A world of possibilities

When you need injection moulded plastic partsAsk us about your options and take advantage of Bi-Plast’s extensive experience in injection moulding technical parts.

Plastic parts

Injection moulding

We have been specialists in injection moulding since 1972, and we put all of our knowledge at your disposal. This means we can help you with material selection, part geometry, and processes.

In our manufacturing facility, we have advanced injection moulding machines that can produce parts with volumes from 0.1 cm3 to 1100 cm3, capable of clamping forces from 25 tonnes up to 350 tonnes.

At Bi-Plast, we offer all types of manufacturing:

-

- High-volume production runs

- Small runs

- Pilot runs

- Prototype / test tools

Examples of injection moulding

Metal replacement: We make some parts where a metal piece has been replaced with a plastic piece, which can result in a lighter, less material-intensive part.

High temperature materials: We also specialize in manufacturing with high-temperature materials, such as PPS, PSU, PEI and PEEK.

Foamed parts: At Bi-Plast, we mould structural foam parts using standard methods, but over the years, we have developed our own methods and know-how to mould parts with very low densities. For example, the density of PE LD and -HD is less than 0.2 g/cm3, and for ABS, PS, PP and POM, the lower limit is around 0.4-0.5 g/cm3, depending on the shape of the part. This opens up interesting opportunities in many areas, such as replacing and improving parts that were previously made of cork, balsa wood or similar materials.

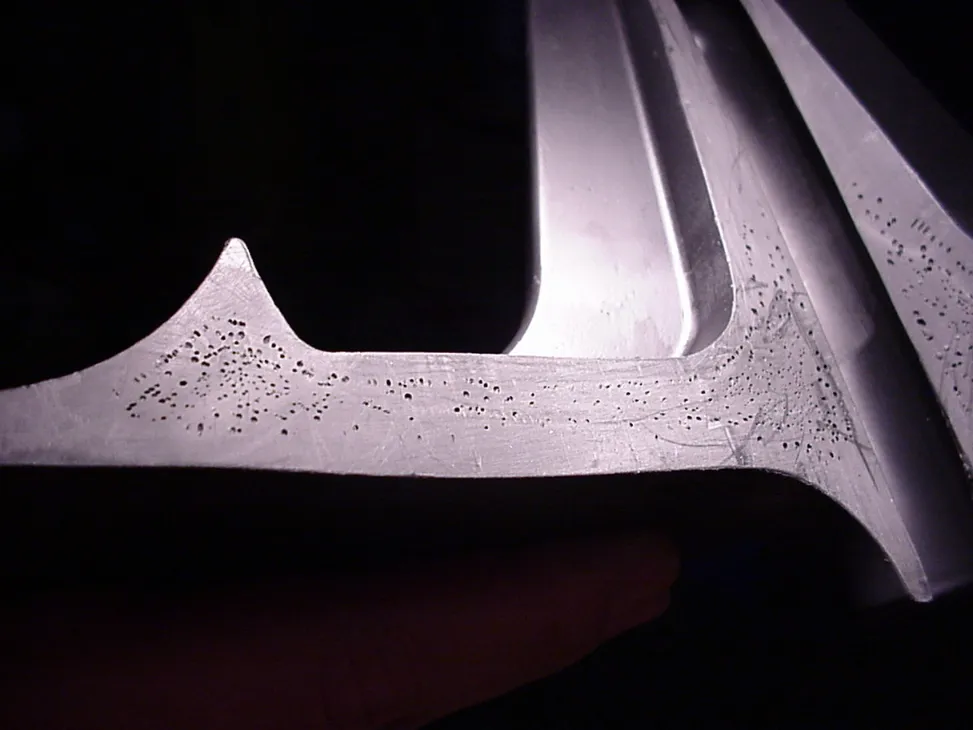

Workpieces with large and varying wall thicknesses: To counteract surface suction and prevent large voids, we use a special moulding process where the thick sections of a workpiece get small air bubbles inside their walls – but not on the surface. Parts moulded using our method, unlike structural foam parts, have surfaces that appear smooth and neat. Additionally, the resulting items are highly suitable for chrome plating, as they have only very low internal tension.

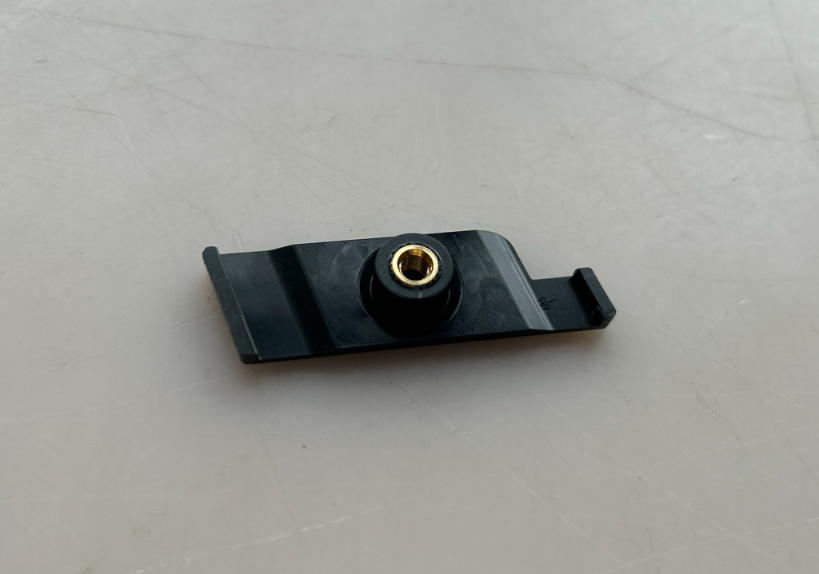

Embedding metal in plastic: If you want to avoid the need for multiple processes, you can have metal embedded in your plastic item, either by an automated or a manual process – whichever is more cost-effective.

Heat Sert: Installing a Heat Sert after producing a part is also an option. This involves heating a threaded brass insert inside the part.

Rubber: At Bi-Plast, you can have rubber items produced from a thermoplastic elastomer with a hardness down to 12 Shore A.

Have you heard about the 2K Monosandwich method?

Contact us

In order to send a message through our contact form, please accept all cookies.

Bi-Plast ApS

Græsholmevej 57

5700 Svendborg

Denmark

VAT-no: 53209718

Phone 62 22 19 00

mail@bi-plast.dk