2K injection moulding

MonosandwichGet the properties of two plastics in a single part with one injection.

2K injection moulding

Monosandwich

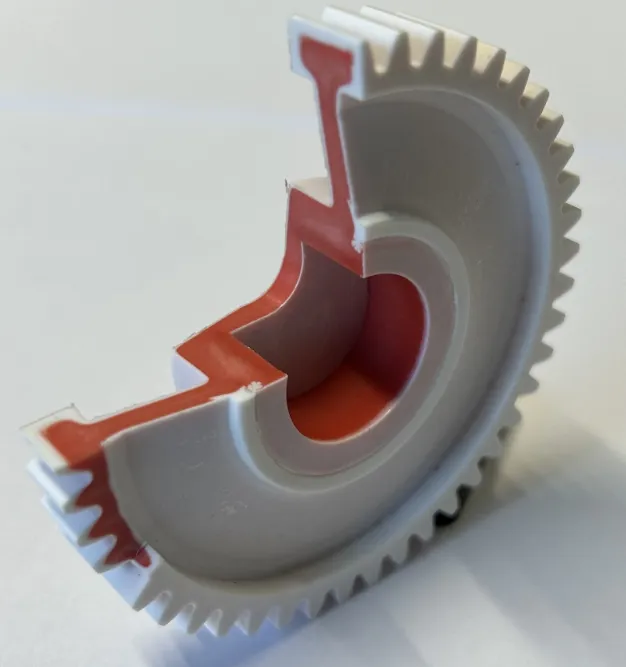

Monosandwich 2K moulding means that with one injection, you get two different plastic materials in the same part.

This allows you to combine different material properties in one mould, such as a strong core with a softer surface layer. You can also choose to use re-granulated plastic material (recycled plastic) in the core and new plastic for the surface layer.

With Monosandwich, you have a unique opportunity to use recycled plastic in the core of your item while still using new plastic on top to give you the surface you want.

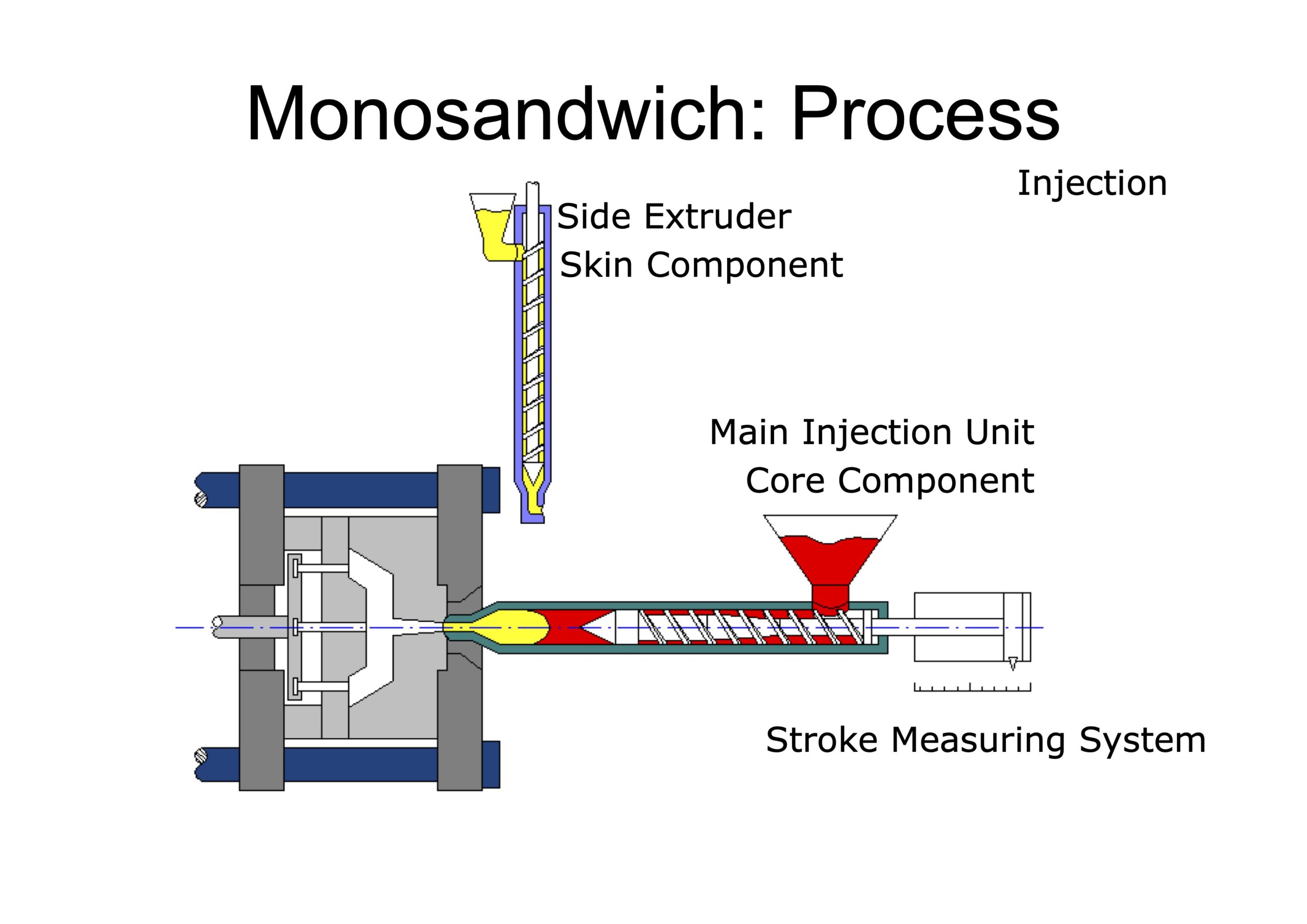

Injection moulding with the Monosandwich method is done using a standard tool. For you, this means that you don’t need to use 2K (two-component) moulding tools, which are significantly more expensive than standard tools.

When working with 2K Monosandwich, the two materials must be chemically compatible, but don’t worry: we can guide you and tell you all about the possibilities for your particular product!

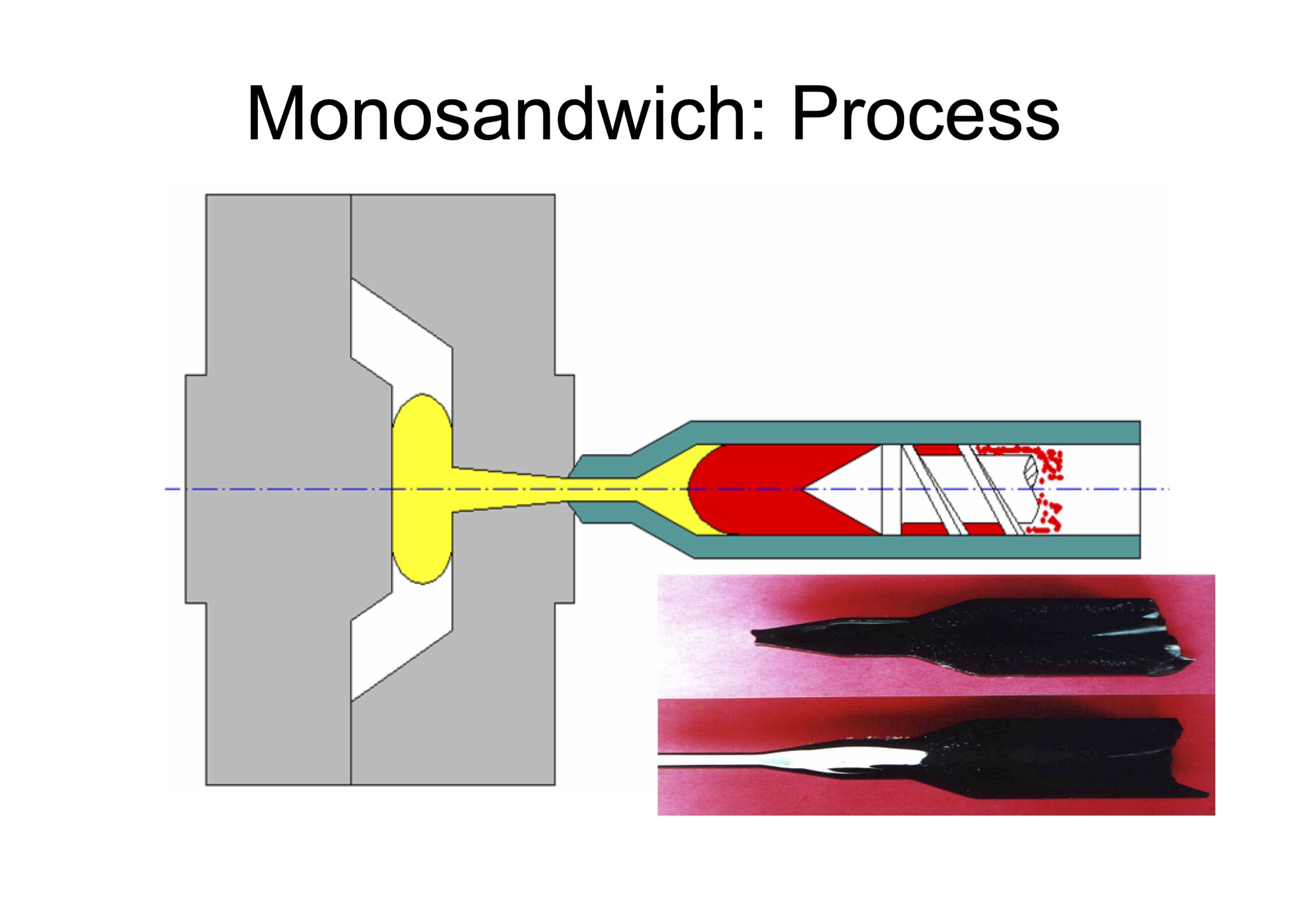

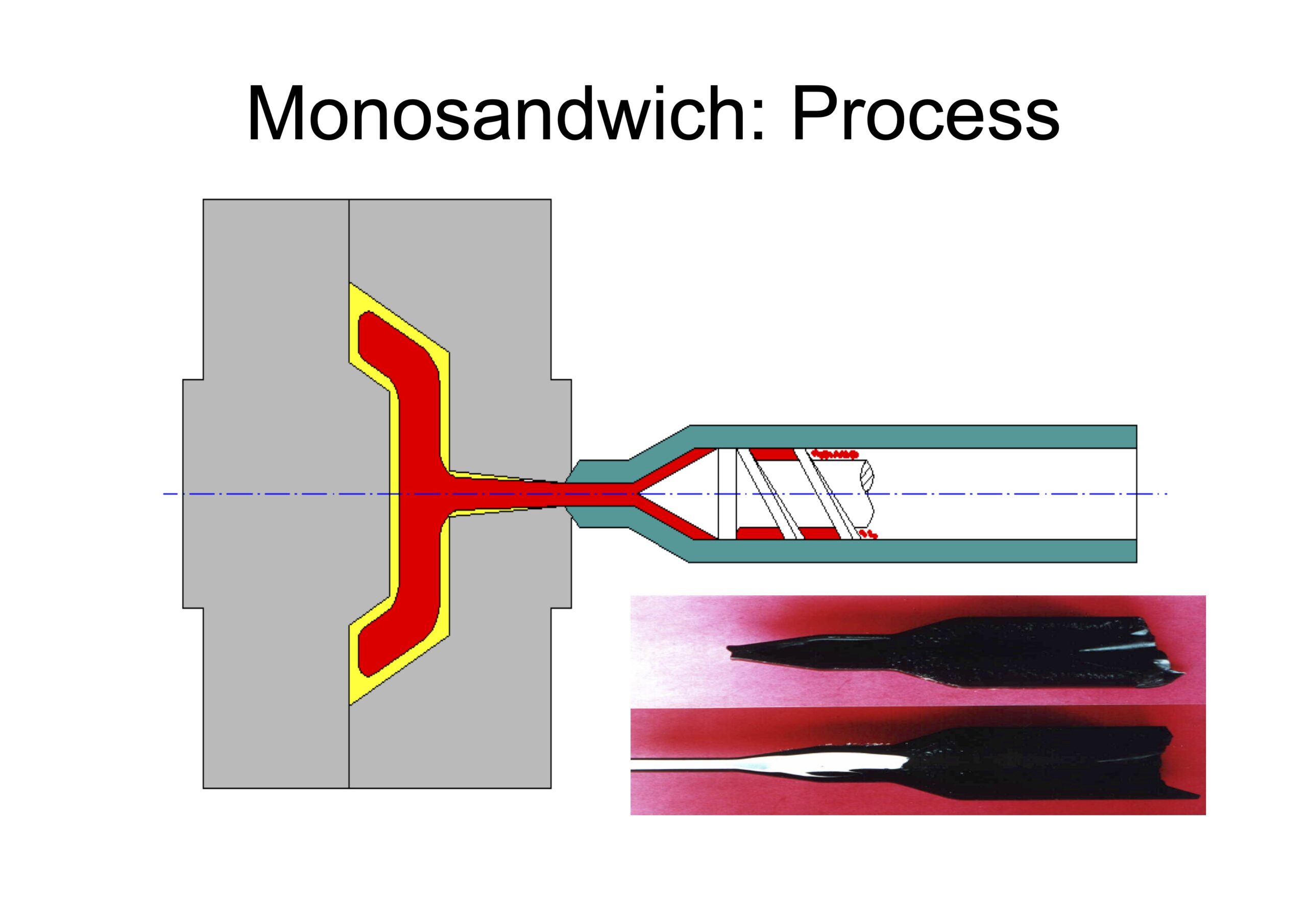

2) Injection of surface material

3) Injection of core material

Monosandwich: Monosandwich: Wire holder with fixed core and clip function made of PP with surface layer made of SEBS.

Monosandwich: Rolling diaphragm, mineral-filled PP core and SEBS membrane.

Bi-Plast has been working with Monosandwich since 1995 and we can show you many more examples than the ones you see on this page.

You are always welcome to contact us for a chat about Monosandwich – it really is an effective 2K method and our customers love it!

And if you’re thinking about recycling, Monosandwich is an obvious starting point. Find out more about Bi-Plast’s work with plastics and the environment here.

Contact us

In order to send a message through our contact form, please accept all cookies.

Bi-Plast ApS

Græsholmevej 57

5700 Svendborg

Denmark

VAT-no: 53209718

Phone 62 22 19 00

mail@bi-plast.dk